The 7 Key Steps in Crafting a Diamond Jewel at Celinni

You've probably already wondered how Celinni diamond jewelry is created. If so, with this jewelry guide, you're in the right place!

It should be known that the profession of jeweler/diamond cutter is a job that requires a lot of precision and know-how.

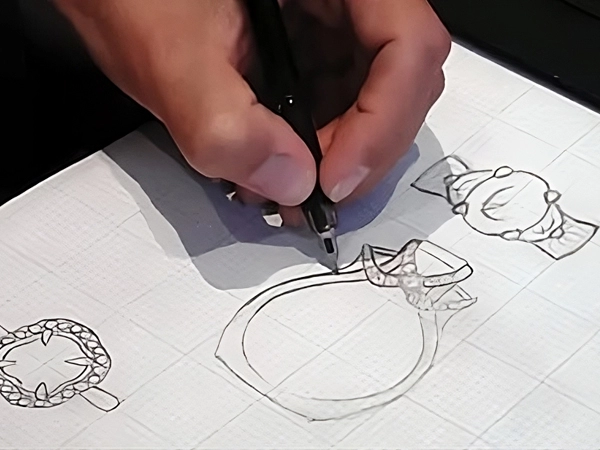

STEP 1: Creation of the diamond jewelry design and its prototype

If the ring or jewel created is a new Celinni creation, there is a whole upstream design process. The jewel will be imagined, drawn and then a prototype will be made. With this prototype, we will try different diamonds and stones on it. We will be able to see if there are things to change or improve.

Prototypes are usually made with materials similar to gold or platinum so that we can see its final result.

This process is the same when you make a custom jewel.

The prototype can also be made in a different way. The world of jewelry is a world that evolves with its time and technology. We use cutting-edge technologies, which makes our work easier. For example, a prototype can be 3D printed.

The jewel will be made of plastic, this is a way to visualize the jewel, but also to create the molds!

STEP 2: Diamond selection

At Celinni, we are first and foremost diamond dealers. What would a diamond dealer be without imagining a diamond jewel? So the selection of the central stone is an important step. Not all diamonds are equal. Diamonds are all unique, two diamonds will inevitably have a difference. These stones are classified according to their characteristics. At Celinni, we always check our diamonds to ensure their quality.

Did you know that the carat is not the most important characteristic? Even when choosing an engagement ring! At Celinni, we work with you to select the most beautiful stone for your budget. We make sure that you find the perfect diamond in your eyes.

STEP 3: Creation of molds

Once the prototype is finalized and validated, we need to create molds so that the jewelry is perfect!

The prototype is placed in the center of a rectangular mold and a mixture resembling resin is poured over it. Once cooled and hardened, the prototype is cut out only to leave a complex imprint structure. From this mold, we create a plaster mold.

The molds are very important because they then allow a precious metal (gold, platinum...) to be poured inside, which when cooled will have the shape of the jewelry!

STEP 4: The Casting

Casting involves taking "beads" of precious metal and heating them (Fun fact: you have to reach their melting point, for example you have to heat gold up to 1064° C so that it melts). Once the metal is melted, the jeweler will pour this hot liquid into the hollow plaster mold. The mold is then set aside to cool.

As it cools, the plaster mold is destroyed in order to recover the metal casting which will, at this point, have the shape of the desired jewel.

STEP 5: Cut, file, crimp and polish

Once the jewel is out of the mold, it will be checked by a quality control. Then our skilled craftsmen will polish and level the jewel in order to eliminate all dust.

Between each step, the jewel undergoes quality checks by qualified people in order to detect irregularities. The diamond jewel must be perfect.

Then comes the most important step of a diamond cutter: setting the famous diamond on this ring. The master setters fix the most beautiful stone in the world in its claws. (Fun fact: the claws are what hold the diamond in place).

Even after this step, the jewel undergoes another quality control. During this last one, we check that the diamond is well fixed and that there is no defect.

It is now necessary to bring out the shine of the metal and the natural brilliance of the diamond. To do this, the jewelry is polished. They can also go through a rhodium plating step, which involves dipping the jewelry in a bath of rhodium.

This rhodium bath will allow the jewel to be protected from daily wear and tear, but will also make it more brilliant than ever.

STEP 6: Personalization? At Celinni it's possible!

At Celinni, it is possible to engrave what you want on your ring! The engraving is offered free of charge. To find out more, find here our article on the engraving of your jewel.

STEP 7: A final quality check

As you may have noticed, Celinni places great emphasis on quality control. Indeed, we ensure that after each step, the diamond jewel is perfect. We deliver diamond jewelry of unparalleled quality to make you the happiest.

A final quality check is carried out when all the steps have been completed. The jewel then goes through our expert hands and is checked with a diamond magnifying glass. We do not neglect any defect, if we notice a roughness or a defect in the manufacture of a jewel we send it directly back to the workshop.

Once the jewel has been checked, we carefully pack it in our beautiful Celinni boxes. We contact you to make sure we have the correct shipping address and then we plan a delivery date together. Generally, once our jewel has passed its final quality check, it will be delivered to you the next day.

An alternative is available to you, the Celinni has showrooms in all four corners of France (Paris, Lille, Lyon, Nice and Bordeaux) but also in Switzerland and Morocco. It is then possible to let us know that you wish to come to one of our showrooms to pick up your jewel. Thus, we plan to send it to the showroom of your choice!

- All Celinni diamonds come from an ethical system: the Kimberley Process. This process aims to stop "Blood Diamond" (diamonds sold illegally to fuel war conflicts).

- You can learn about gemology in our showrooms. To find out more, click here (put link Introduction to gemology in our showrooms).

- Diamond jewelry requires specific maintenance, to find out more, find our article on diamond jewelry maintenance here. (Put link diamond jewelry maintenance).

Congratulations! You know everything about the manufacture of Celinni diamond jewelry. Do not hesitate to contact us for more information.

Also find :

FAQ – Everything You Need to Know About Making a Diamond Jewel at Celinni

1. How long does it take to create a custom-made jewel?

On average, it takes 4 to 6 weeks to craft a custom-made jewel at Celinni. This includes design conception, diamond selection, mold making, fabrication, finishing, and quality checks.

2. Can I choose the diamond that will be set in my jewel?

Yes, at Celinni you can select your diamond based on your preferences and budget. Our expert gemologists will guide you through choosing the perfect stone, considering the 4Cs (carat, color, clarity, cut).

3. What materials are used to create Celinni jewels?

Celinni exclusively uses noble materials such as 18k gold (yellow, white, or rose) and platinum. All our jewels are set with certified natural diamonds and crafted in accordance with the finest French jewelry traditions.

4. Can I personalize my jewel with an engraving?

Yes, Celinni offers complimentary custom engraving. You can add a name, date, or message inside your ring or any other jewel when placing your order.

5. How can I be sure the jewel passed quality control?

Each Celinni jewel undergoes strict quality control checks at every stage of production. Before delivery, a final inspection is performed with a jeweler's loupe to ensure the piece is flawless.

CUSTOMER TESTIMONIALS

ON YOUR DIAMOND

Read our customer testimonials

NEWSLETTER

Sign up to receive the latest news regarding

the products and services CELINNI, and much more.

This website uses its own and third-party cookies to improve our services and show you advertising related to your preferences by analyzing your browsing habits. To give your consent to its use, press the Accept button.

Cookie preferences

| Cookie | Provider | Purpose | Expiry |

|---|---|---|---|

| PHP_SESSID | www.celinni.com | The PHPSESSID cookie is native to PHP and allows websites to store serialised status data. On the website it is used to establish a user session and to pass state data through a temporary cookie, which is commonly known as a session cookie. These Cookies will only remain on your computer until you close your browser. | Session |

| PrestaShop-# | www.celinni.com | This is a cookie used by Prestashop to store information and keep the user's session open. It stores information such as currency, language, customer ID, among other data necessary for the proper functioning of the shop. | 480 hours |